Complete Guide to Aluminum Surface Treatment Processes, Worth Collecting

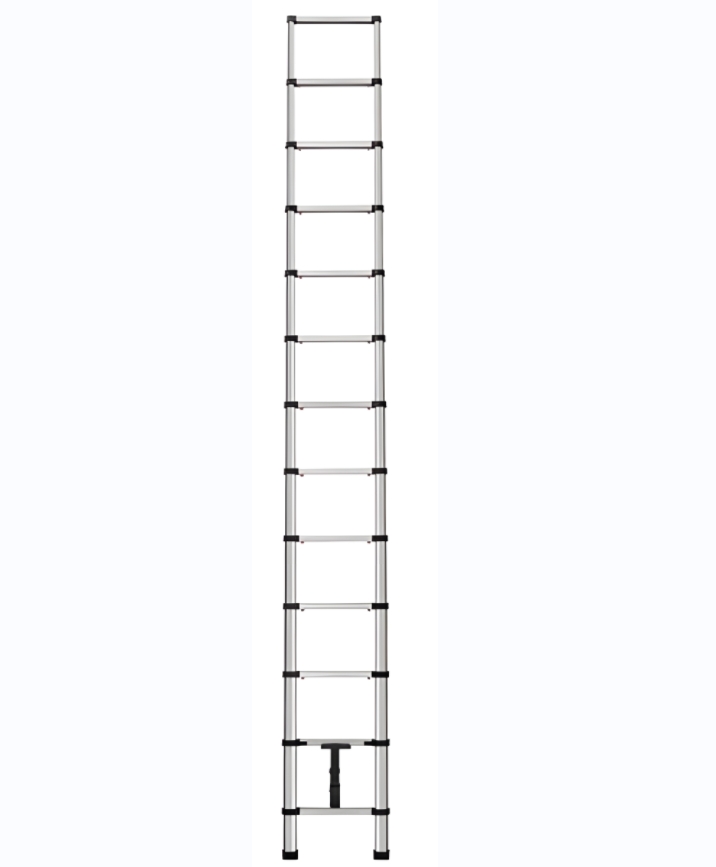

NIQI LADDER factory customize your aluminum ladder surface treatments

Aluminum Surface Treatment:

Surface treatment refers to the process method of artificially forming a surface layer on the surface of the base material, which has different mechanical, physical, and chemical properties from the base. The purpose of surface treatment is to meet the product's requirements for corrosion resistance, wear resistance, decoration, or other special functions.

Aluminum Surface treatment processes include: anodizing, electrophoretic coating, powder coating, and wood grain transfer.

Anodizing:

Anodizing is an electrochemical treatment process that enhances the corrosion and wear resistance of aluminum profiles by forming an aluminum oxide film on their surface. This oxide layer can be colored to change the color of the aluminum profiles, thereby increasing their decorative appeal.

Electrophoretic Coating:

This is a coating method that utilizes an external electric field to direct the migration of pigment and resin particles suspended in an electrophoretic bath towards one of the electrodes, where they deposit on the substrate surface. Developed over the past 30 years, electrophoretic coating represents a unique method of film formation and is the most practically significant application technique for water-based paints. It features water solubility, non-toxicity, and ease of automation control, quickly gaining widespread use in industries such as automotive, building materials, hardware, and home appliances.

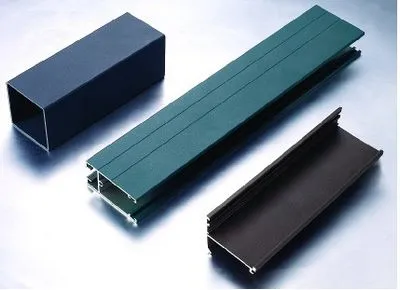

Powder Coating:

This process involves using a powder spraying device (electrostatic spray painter) to apply powder coating to the surface of a workpiece. Under the effect of static electricity, the powder evenly adheres to the surface of the workpiece, forming a powdery coating. This powdery coating is then cured through high-temperature baking and leveling, resulting in a final coating with varying effects depending on the type of powder coating used. The results of powder coating in terms of mechanical strength, adhesion, corrosion resistance, and weatherability are superior to those of painting processes, though it is more costly than painting.

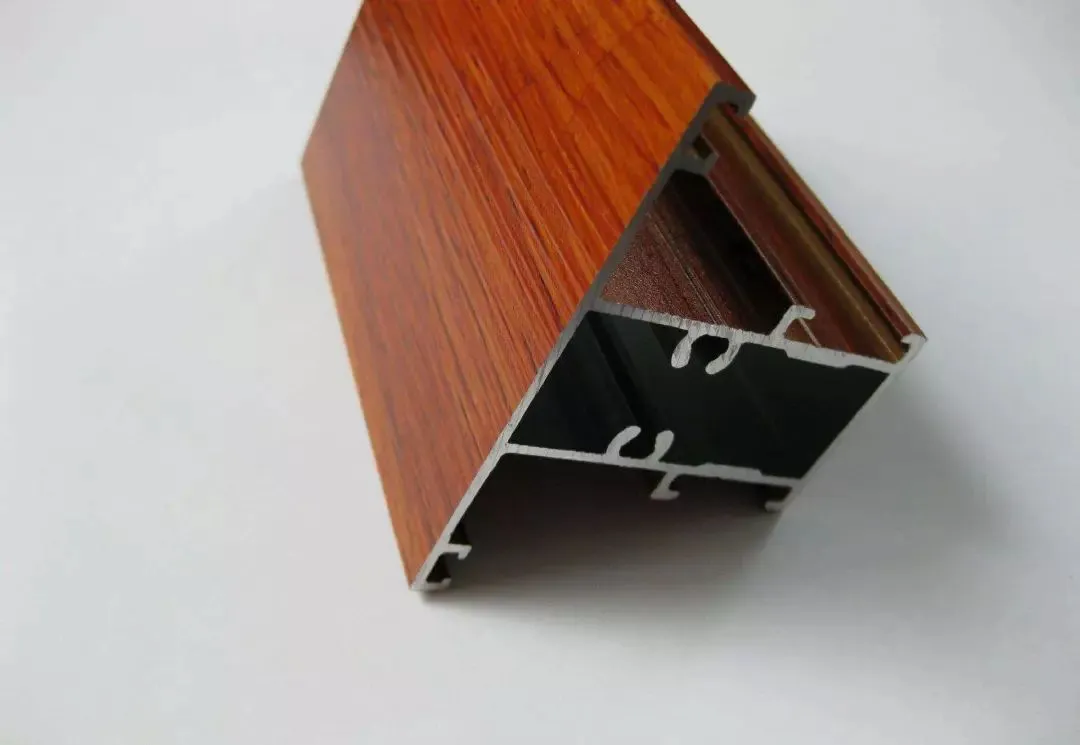

Wood Grain Transfer:

After electrostatic powder coating on a metal surface, a vacuum wood grain transfer equipment is used to apply high-temperature and pressure over the coated material. This process causes the ink from the transfer paper or film to sublimate and quickly transfer into the already sprayed or electrophoretically coated layer, effectively imprinting a wood grain pattern onto the surface.

NIQI customized aluminum surface treatments

NIQI LADDER can provide you with customized aluminum surface treatments, meeting your various personalized requirements for ladder color&decoration etc, while effectively enhancing the functionality of aluminum ladders in terms of mechanical strength, adhesion, corrosion resistance, and weatherability.YOU can contact us and tell us your requirments.

example pics

example pics

+86123456789

+86123456789

+86123456789

+86123456789